Success Stories

Atlantis Strength

Atlantis Strength is Canada’s largest commercial strength equipment manufacturer. They employ a careful balance of in-house and out-sourced methodology, and CAD technology that dictates every cut, weld, and part used during their 6-stage manufacturing process. Atlantis Strength was founded by Canadian bodybuilding champion Raymond Sansoucy over 30 years ago and has become an industry leader, offering 240 pieces of customizable strength equipment to customers around the world.

Atlantis Strength has been partnered with SolidCAD for several years now and continues to work together to ensure they have the best software to meet their growing needs as they overcome the challenges in their industry.

Improving Communication and Increasing Productivity with Autodesk Vault Professional®!

The Challenge

As Atlantis Strength rapidly grew, so did their need for data management. They struggled with efficient communication between the manufacturing and engineering teams, and often found that their projects took longer than necessary due to the lack of centralized information. Despite their highly skilled staff, it was difficult to keep information up to date. This reduced productivity and prevented the team from working at their full potential, causing massive delays.

The Solution

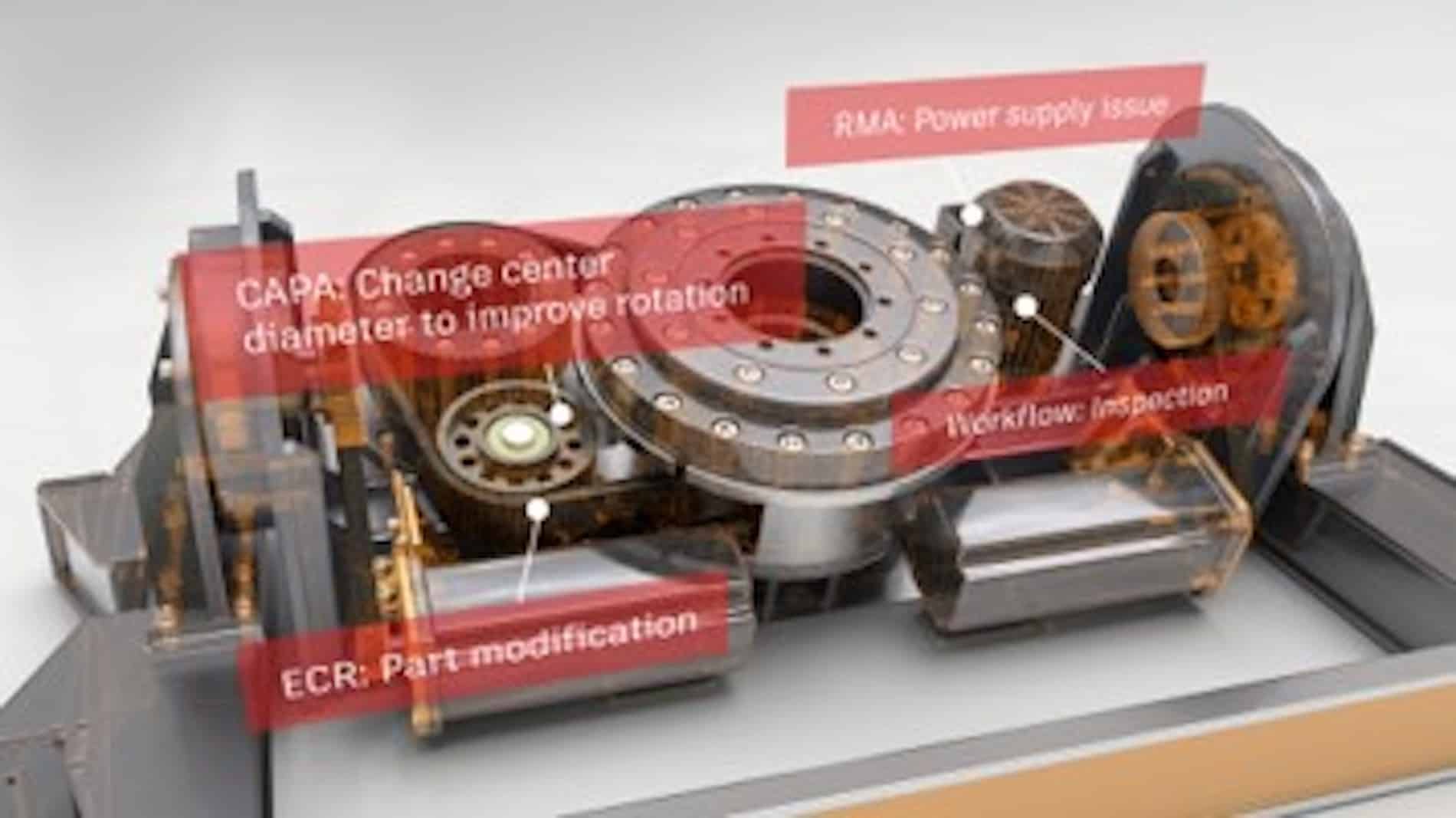

Atlantis Strength realized that their workflow needed improving and that efficient communication was crucial to the productivity of their team. Searching for a solution, they reached out to SolidCAD and asked what their best option was. SolidCAD’s representative introduced them to Vault Professional, the product data management software that would help streamline their current manufacturing workflow.

Vault Professional has allowed the company to easily manage all their design and engineering data and take control of their product development processes. Staff can work from data without worrying about out-of-date documents that could result in engineering errors or miscommunication between departments.

The Results

- Project completion time has reduced significantly, resulting in their productivity improving by 75%.

- Staff has immediate access to the latest versions of designs, reducing the amount of design errors.

- Communication between teams has greatly improved.

Testimonial

Testimonial

The difference was like night and day; we’ve completely streamlined our workflow and the timeline of our projects has really improved. This solution is fantastic. To anyone else in our position, do not hesitate to reach out to SolidCAD. Their technical team is highly skilled. The communication, the training, their availability, it’s everything we needed.

- Diego Fernandez

Senior Designer at Atlantis Strength

Products & Services Used

- Vault Pro

- Implementation and Training

- Support