This story was originally published by on the Bluebeam Blog.

Discover how Compare Documents and Overlay Pages by Bluebeam transforms managing documents with precision and visual clarity.

In the world of digital document management in the architectural, engineering and construction (AEC) industry, precision and efficiency are paramount. Professionals across the industry rely on tools that streamline their workflows and enhance collaboration.

Bluebeam offers two powerful features—Compare Documents and Overlay Pages—each designed to serve specific purposes. In this article, we’ll delve into the intricacies of these tools to help users make informed decisions on which to use, and when.

Compare Documents: A Closer Look

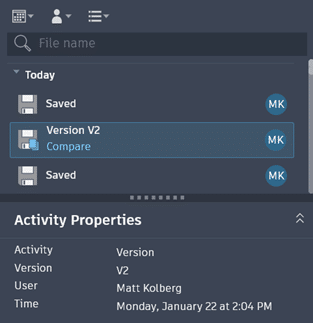

Bluebeam’s Compare Documents feature is a robust tool designed to highlight the differences between two versions of a document. This can be especially invaluable in scenarios where document revisions are frequent.

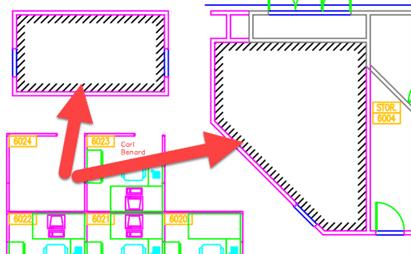

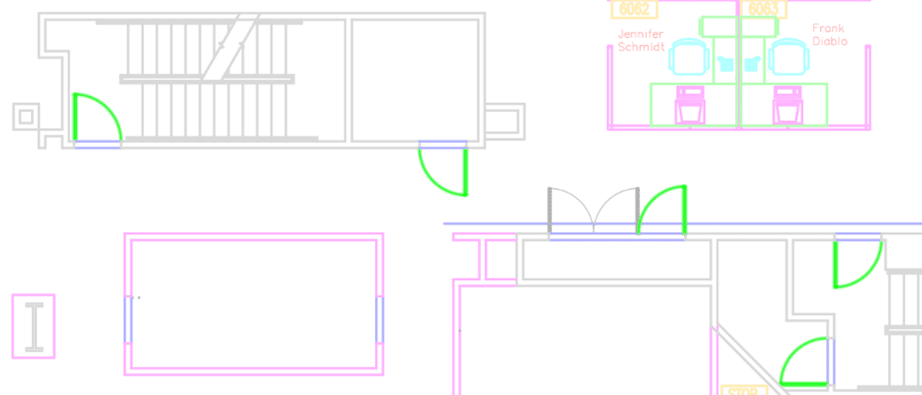

When a user initiates the Compare Documents function, Bluebeam Revu meticulously analyzes the content of the selected documents and generates a comprehensive report highlighting any discrepancies. This includes additions, deletions and modifications made between the two versions. The software employs a color-coded system, making it easy for users to identify changes at a glance. Typically, additions are highlighted in green, deletions in red and modifications in blue; for Compare Documents, cloud markups are added around the differences.

The utility of Compare Documents extends beyond textual content. It can also identify changes in graphical elements, providing a holistic overview of alterations in the document. This feature not only accelerates the review process but also minimizes the risk of oversight.

Overlay Pages: Unveiling the Integration

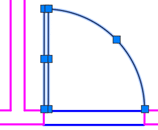

Overlay Pages is another powerful feature within Bluebeam’s arsenal, designed to facilitate precise document comparisons and analysis. Unlike Compare Documents, Overlay Pages allows users to superimpose two versions of a document on top of each other, providing a visual representation of their differences.

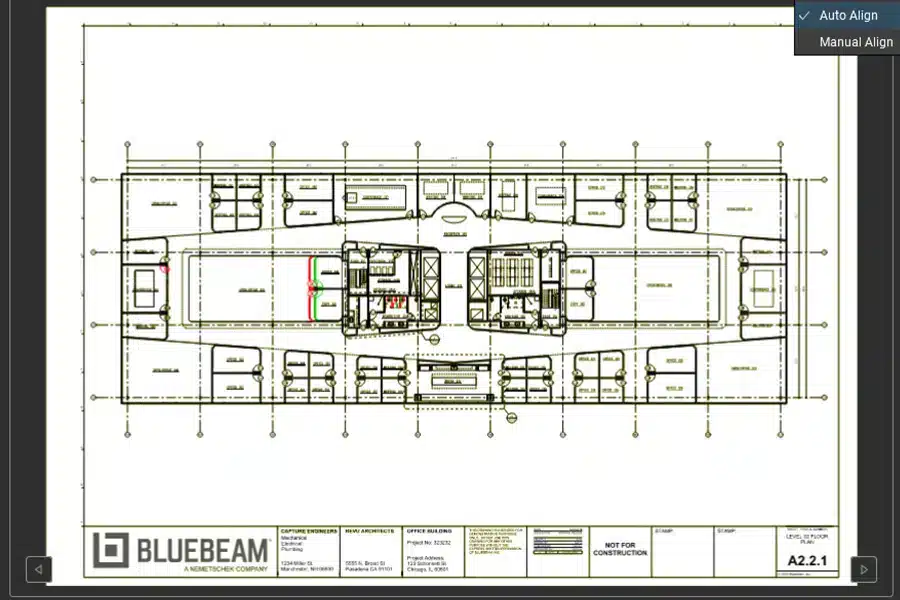

This feature is particularly beneficial when dealing with architectural plans or any document where graphical elements are of utmost importance. By overlaying the pages, users can visually assess discrepancies in the placement of elements, ensuring that the design conforms to specifications. This method of visual inspection can be more intuitive for certain types of documents, providing a complementary approach to the text-centric Compare Documents feature.

Integration for Comprehensive Analysis

While Compare Documents and Overlay Pages serve distinct purposes, their integration can offer a comprehensive solution for users seeking an exhaustive analysis of document revisions.

By first employing Compare Documents to identify textual changes, users can then turn to Overlay Pages to visually inspect the graphical alterations. This combined approach ensures a thorough examination of both textual and visual elements, leaving no room for oversight. The seamless integration of these features in Bluebeam empowers users to achieve meticulous precision in their document review processes.

Auto Align Makes Compare Documents and Overlay Pages Even Better

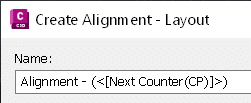

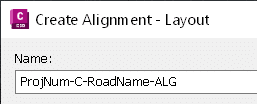

Released in April 2024, Revu 21.1 gives Compare Documents and Overlay Pages an overhaul. Not only has the user interface been greatly improved for easier navigation and previews of the results, but Bluebeam has also added AI. Auto Align is an AI-enabled capability allowing for documents and pages to align automatically.

Auto Align reduces the tedious, error-prone steps of manually aligning three points on each drawing revision, so users can understand the differences between them faster. Bluebeam customers currently use the Overlay and Compare features more than 5 million times a year. With the Auto Align option, users can now understand the differences in their documents and pages up to 80% faster.